Filter types

Customised filters and screens - the right solution for every application.

Our individual solutions for filters and screens are designed for specific applications. Small and technically complex installation spaces require innovative filter designs. Technically demanding applications require reliably functioning and optimally designed filter screens. Because we know that your application involves very special demands and operating conditions, we provide customized filter solutions, wich exactly match your applications. There are practically no limits to geometries and materials. See for yourself.

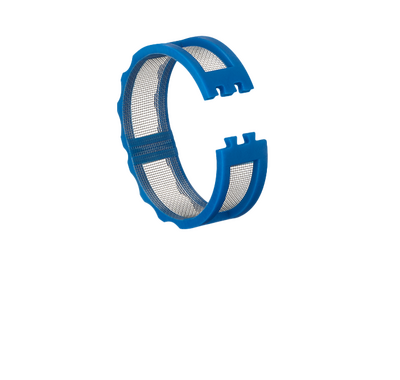

Clip filters

and FLEXi-Clip

Clip filters

and FLEXi-Clip

Open plastic ring filters for simple installation

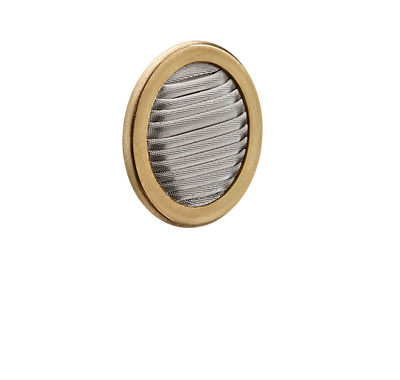

Hybrid filter screens

Hybrid filter screens

Filters and screens with metal mesh and plastic injection moulding

Plastic filters

Plastic filters

Customised filters and screens with plastic mesh

Metal filters

Metal filters

Customised metal filter screens

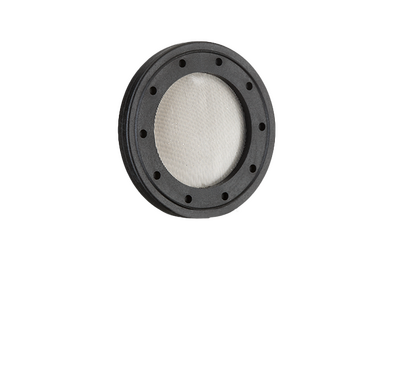

Combination filters

Combination filters

Valve housing with screen and sealing function

Disc filters and cylindrical filters

Disc filters and cylindrical filters

A wide range of potential applications for disc and cylindrical filters

Fully injected

molded parts

Fully injected

molded parts

Lightweight, flexible, customizable

Material

Only the best material

for you filter.

The material used for your filter depends on the reference data of your specific application situation. Factors such as:

- Operating temperature

- Flow rate

- Media and pressure resistance and form stability

- Degree of filtration

- Service life

- Replaceability

- Self-cleaning effect

- and last but not least the vibration resistanc

play a crucial role. Our experience from more than a thousand filter projects for leading customers from all types and branches play a major role here. With our advice on the choice of material for your filter you profit from our know-how of the fabric and plastic types, geometries and demands on the production. Whether plastic mesh or wire mesh, hybrid filter, plastic filter or metal filter. Whether plastic- or wire mesh, hybrid filter systems, plastic or metal filters, filters with integrated screens and sealing function, Clip- , Disk-, or cylindrical Filters, look no further.

Filter fineness

Up to 0.15 microns

for filtering bacteria.

Membrane filters with a fineness of up to 0.15 µm can be manufactured in series using injection molding, enabling the filtration of bacteria and fungi.

Sizes

Impressively small.

Despite their compact dimensions, our filters offer high filtration performance and contribute to increased efficiency in sensitive processes.

Thermoplastics

We help you choose

the right plastics.

The material used for your filter depends on the basic data of your specific application situation.

As filter specialists, we use high-temperature plastics in the production of our filters because they are robust and heat-resistant. These materials enable us to manufacture filters, that can withstand extreme temperatures while offering high filter performance. By using these plastics, we offer our customers durable and efficient products.

We use engineering plastics in the manufacture of our filter components to produce stable and precise components. These materials offer high mechanical strength, dimensional stability, and chemical resistance, making them ideal for demanding applications. Their low weight and versatile processability also support efficient and economical production.

We primarily use standard plastics in less demanding areas of our filter production, where there are no extreme mechanical or thermal requirements. They enable cost-efficient manufacturing of simple components and thus contribute to the economic efficiency of our products. Despite their simpler properties, they offer good processability and sufficient stability for many applications.

Film

What makes a filter a Küfner filter?

From the initial idea to the design and series production, Küfner is your one-stop shop for everything. Our high level of vertical integration with our own mold and tool making allows us to respond quickly and flexibly to all specific requirements.

All media

For every application.

Our filters can filter all types of media, whether air, water, or gas—there are no limits. Temperature resistance, flow capacity, and media resistance are just a few of the many requirements a filter must meet in order to satisfy your high standards. Our filter screens are precisely tailored to the respective application. They keep liquids and gases free of particles and protect technically complex components from damage and malfunction. Our customers' applications place high demands on our products in terms of pressure, temperature, and aggressiveness of the media to be filtered. The possible applications for our filter elements are virtually unlimited.

Gas

Water

Fuel

Blood

Production

Your expectations are our benchmark.

From sample filters to series production.

You have invested a lot to make your product successful. It is unique in many ways and can therefore compete on the global market. A filter can protect your product and make it better or safer, if it fits your application exactly. And if it receives the same attention that you gave your product during its development. Let's work together to figure out how we can customize your filter, so that it fits seamlessly into your product.

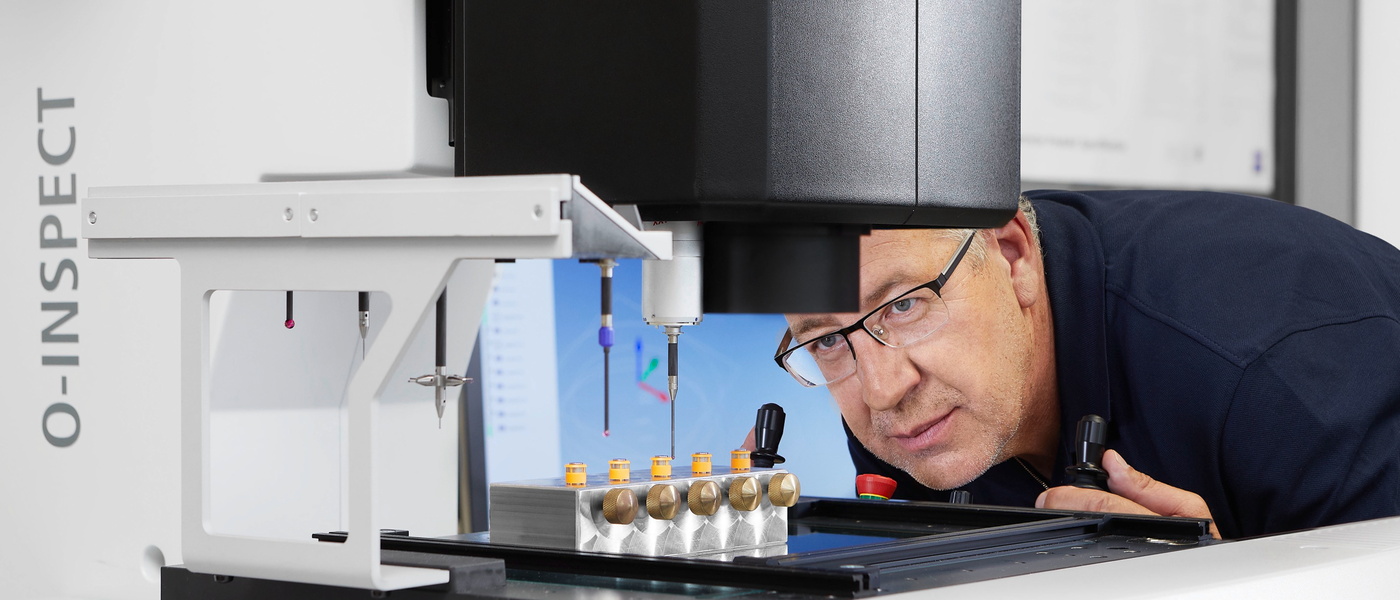

Inspection

Seamless control.

Because we know, how crucial safe and clean filters are for your application, we always equip our production facilities with fully automated testing systems. In addition to fully automated Camera Inspections of the Filters and Screens, we are also able to carry out cleanliness and residual dirt analyses, to ensure you only receive filters of impeccable quality from us.

We are certified according to IATF 16949 and EN ISO 13485. Our environmental management system is certified according to ISO 14001. Repeated awards from our customers prove our competence in filter manufacturing and our reliability as a filter supplier.

Supplier

Reliable delivery.

For more than half a century, we have been designing, producing, and supplying application-specific filters and screens to customers all over the world. Numerous OEMs and suppliers benefit daily from our expertise in filter manufacturing and filter delivery. Our close connection to our customers' production planning and information systems is a key reason why our filter deliveries are available at the right time and in the right quantity at our customers' production sites in Europe, Asia, and America.