Customised

filters and screens for

Aerospace technology.

Applications in aerospace technology place high technical demands on our filter screens. The highest safety standards, combined with extreme load profiles, characterize this product family.

Are you interested?

Don't hesitate to contact us!

Overview

Areas of application

Our high-precision screening and filter solutions protect critical systems in aerospace technology. They reliably filter contaminants from liquids and gases, ensuring the longevity and safe operation of engines, hydraulic systems, and many other sensitive components.

Advantages in aerospace technology

In aircraft and spacecraft, our solutions filter contaminants from fuel, hydraulic, and brake systems. This protects critical components, ensures reliable operation even under extreme conditions, and increases the safety of aerospace missions.

- Maximum protection for sensitive systems

Our filters reliably keep abrasion, rust, and particles out of hydraulic, fuel, brake, cooling, and oil systems. - Increased operational safety

Clean media ensure precise control, stable performance, and prevent system failures—crucial for safety in aerospace. - Longer component life

Filters protect valves, pumps, engines, and turbines from wear, which extends maintenance intervals and reduces operating costs. - Optimal performance

Constant media cleanliness ensures efficient cooling, lubrication, and energy supply—for maximum performance.

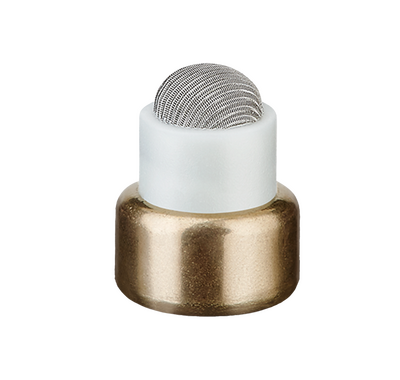

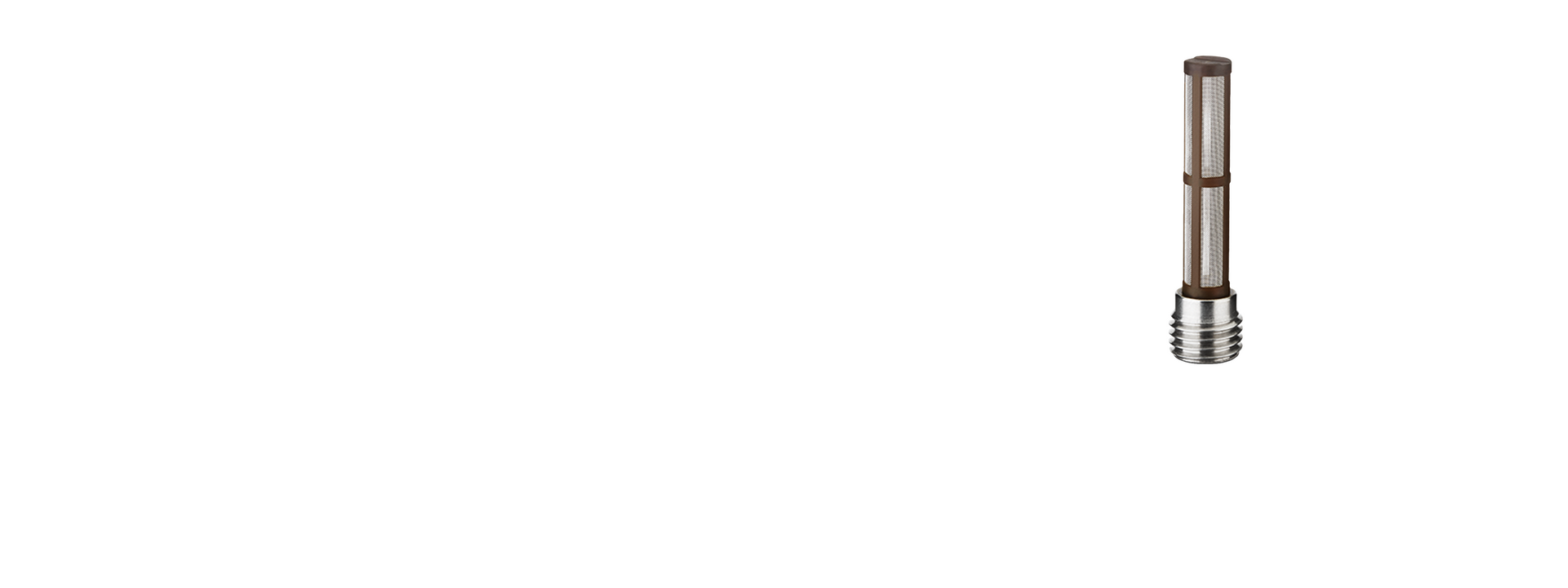

Filter types

Your requirements are our motivation.

For the best filter.

From bathroom faucets to aircraft nose wheels, our filters can be found practically everywhere. They prevent malfunctions in sensitive units and enable a wide variety of applications to function smoothly. Some of our filters are smaller than a pinhead, yet they are indispensable when it comes to ensuring the functionality of your products.

Production

Your expectations are our benchmark.

From sample filters to series production.

You have invested a lot to make your product successful. It is unique in many ways and can therefore compete on the global market. A filter can protect your product and make it better or safer, if it fits your application exactly. And if it receives the same attention that you gave your product during its development. Let's work together to figure out how we can customize your filter, so that it fits seamlessly into your product.

Key Facts

We stand for quality.

When you have us manufacture your filter, you are entrusting us with an important role in your product's value chain. Our awareness of this responsibility is reflected in all our processes and standards.

Made in Germany

> 70 years of expertise

Worldwide

Short-term

Reliable

Service