Are you interested?

Don't hesitate to contact us!

Overview

Areas of application

Our high-precision sieve and filter solutions ensure maximum purity and reliability in medical applications. They protect critical components in medical devices from particles, contaminants, and failures, which is essential for proper functioning and compliance with strict quality and hygiene standards.

Filter fineness

Up to 0.15 microns

for filtering bacteria.

Membrane filters with a fineness of up to 0.15 µm can be manufactured in series usinginjection molding, enabling the filtration of bacteria and fungi.

Advantages

- Competitive advantage thanks to cleanroom class 7c

- ISO DIN EN 13485:2016 certified

- Micro and multi-component injection molding possible

- High purity and reliability

Effectively protect medical devices from contamination and ensure safe, trouble-free operations. - Ensuring hygiene

Meets strict quality and hygiene standards for use in medical facilities. - Protection of sensitive systems

Prevents damage and failures in devices and supply systems caused by particles and foreign substances. - Reliable diagnoses

Ensure the accuracy of analysis and diagnostic devices through clean filter media. - Optimal patient care

Guarantee clean media such as gases and liquids for safe and precise treatment.

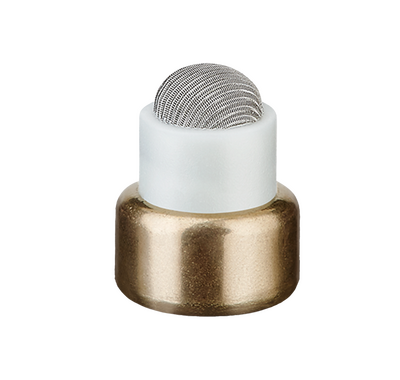

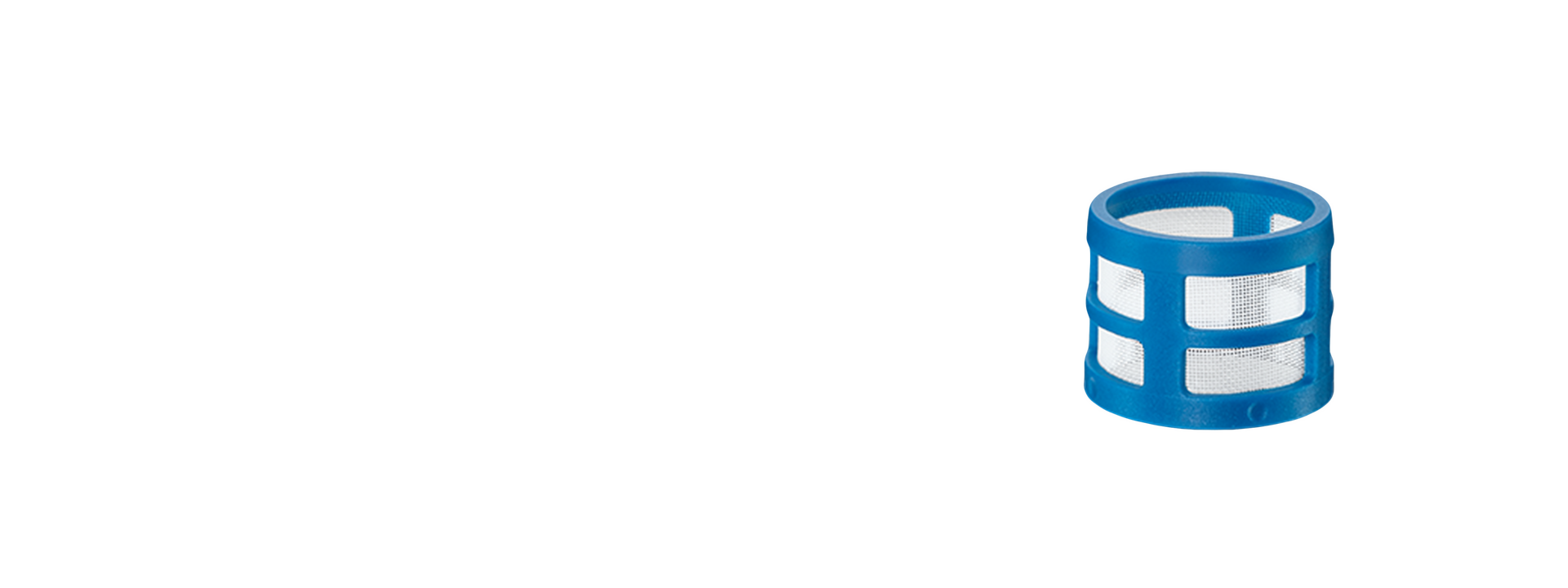

Filter types

Your requirements are our motivation.

For the best filter.

From bathroom faucets to aircraft nose wheels, our filters can be found practically everywhere. They prevent malfunctions in sensitive units and enable a wide variety of applications to function smoothly. Some of our filters are smaller than a pinhead, yet they are indispensable when it comes to ensuring the functionality of your products.

Production

Your expectations are our benchmark.

From sample filters to series production.

You have invested a lot to make your product successful. It is unique in many ways and can therefore compete on the global market. A filter can protect your product and make it better or safer, if it fits your application exactly. And if it receives the same attention that you gave your product during its development. Let's work together to figure out how we can customize your filter, so that it fits seamlessly into your product.

Key Facts

We stand for quality.

When you have us manufacture your filter, you are entrusting us with an important role in your product's value chain. Our awareness of this responsibility is reflected in all our processes and standards.

Made in Germany

> 70 years of expertise

Worldwide

Short-term

Reliable

Service